Hot spots in plastic-bonded explosives (PBX)

Importance of hot spot formation, growth and extinction in PBX microstructures

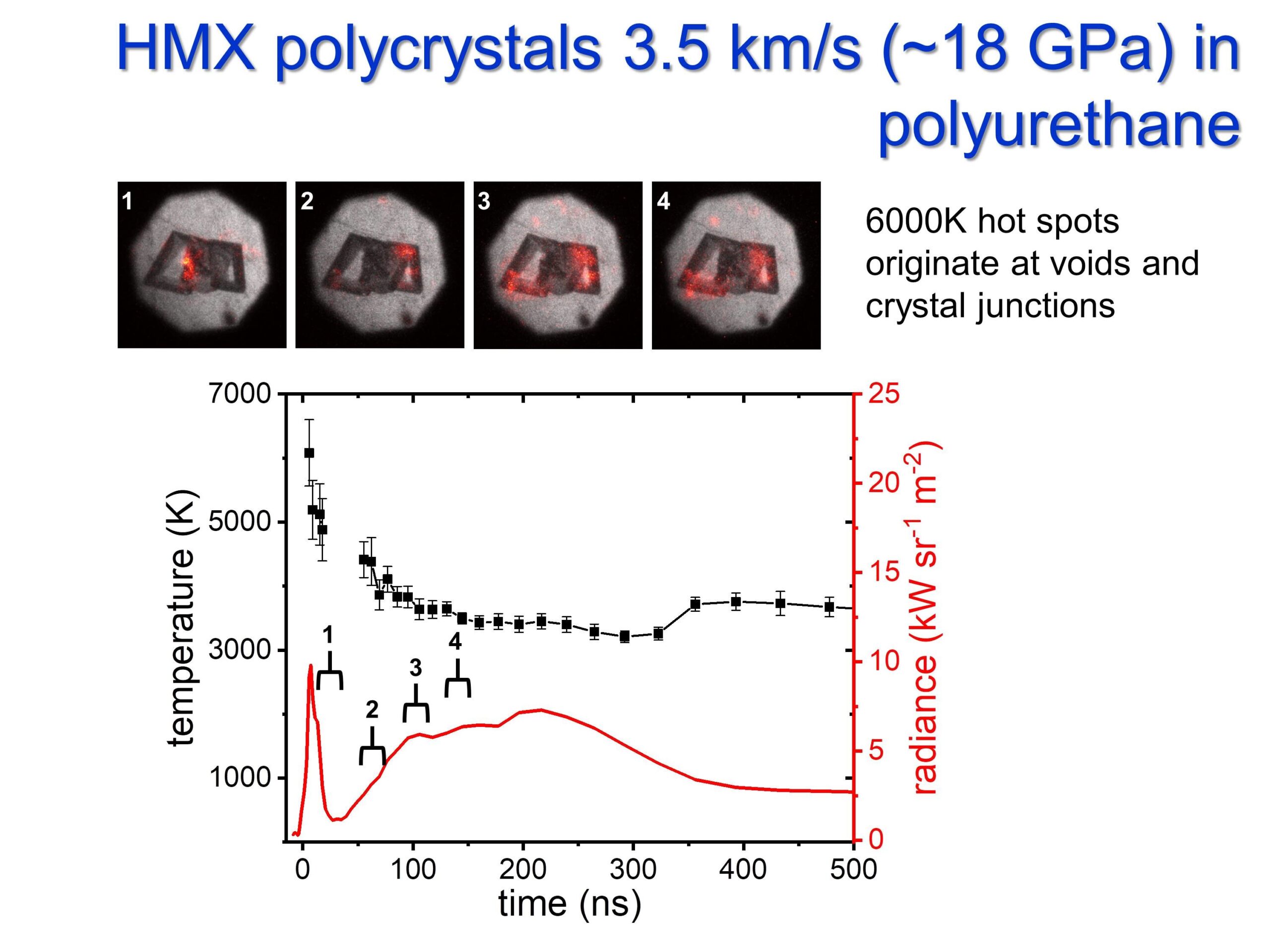

High performance explosives are usually fabricated as plastic-bonded explosives (PBX), consisting of energetic crystals and polymer binders. PBX charges have a complex microstructure that can concentrate the energy from shock waves into small volumes to produce the so-called “hot spots”. Hot spots are integral to PBX function and controlling hot spots can control the explosive output or can make the explosive less sensitive to accidental ignition. Hot spots are intense extreme reactions initially localized in time and space. Watching hot spots grow or decay provides information needed to produce kinetic models of energetic material chemistry. The figure to the right shows the growth of hotspots depicted as red smears superimposed over the image of initial unreacted HMX polycrystal.

Peeking into single crystals of HMX

We study hot spots by encasing small energetic microstructures in a transparent polymer so we can watch them in real time during a flyer plate impact. Recently we looked at the powerful explosive HMX in the form of a single crystal in a polyurethane binder. As shown above, 6000K hot spots are produced at junctions between polycrystals. Reference: B. P. Johnson, X. Zhou, and D. D. Dlott, Shock Pressure Dependence of Hot Spots in a Model Plastic-Bonded Explosive, J. Phys. Chem. A 126, 145-154 (2022). S. Roy, B. P. Johnson, X. Zhou, Y. T. Nguyen, D. D. Dlott, and H. S. Udaykumar, Hot spot ignition and growth from tandem micro-scale simulations and experiments on plastic-bonded explosives, J. Appl. Phys 131, 205901 (2022).

Developing predictive capabilities

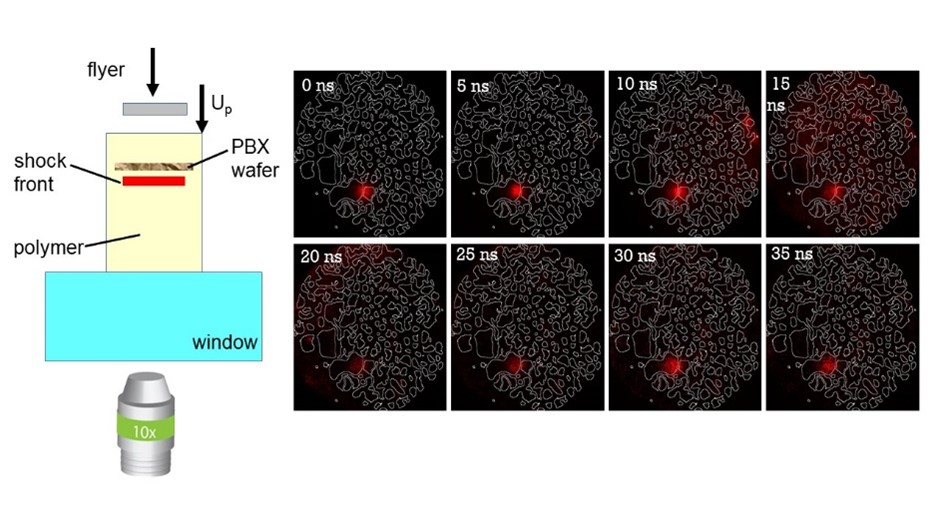

Our current efforts are focused on using machine learning to predict where hot spots will appear and how fast they will grow. The idea is that we should be able to look at the PBX and make such a prediction. However PBX are opaque so we can only look at the surface. Now we have developed a method to make a PBX wafer that is about one crystal thick. As depicted below, this wafer is embedded in a transparent polymer so we can watch it as the shock passes through. A series of video images shows a hot spot evolving in time. (The white outlines show where the HMX crystals are located and the red regions are the hot spot). Reference: D. Sellan, X. Zhou, L. Salvati III, S. K. Valluri, and D. D. Dlott, In operando measurements of high explosives, J. Chem. Phys 157, 224202 (2022). The PBX wafers have a large enough area that we can shock about 50 spots on each wafer. Recently we have obtained enough data to show machine learning can look at an image of the wafer and predict where the hot spots develop and how fast they grow.